HIGH/ULTRA-HIGH RESOLUTION

The sophisticated UT Piglet® system from our partners comprises a versatile, multi-body, centered pig that uses ultrasound technology for scanning pipe wall.

The ultrasound sensor, with rotating mirror, measures the complete circumference of the pipe while the wall thickness, inner radius and distance measurements are monitored online in real-time during the inspection run, via a fiber-optic umbilical cable and are stored internally in the Piglet®. This allows the overall condition of the pipeline, including defects, to be viewed using the umbilical, while the raw ultrasonic data is stored for detailed post-processing analysis.

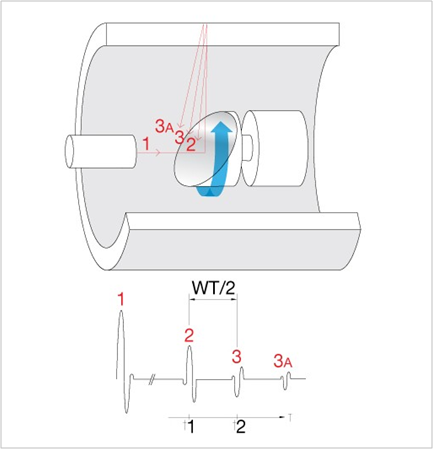

The Ultrasonic system uses echo sounding whereby a sound pulse is sent from the transducer in the middle of the pipe in the direction of the pipe wall where the sound pulse will be partially reflected back to the center of the pipe to be detected by the same transducer. Part of the sound pulse will not be reflected by the inner pipe wall but will travel through the pipe wall and will reflect back from the outer pipe wall. The time difference between both reflections (inner and outer) determines the wall thickness at that point as shown in the accompanying diagram.

Benefits of this UT Measuring System include:

- Standard, high or ultra-high resolution capabilities

- Options to adapt frequency and detectability.