PRECISION SCAN OF RISKY AREAS

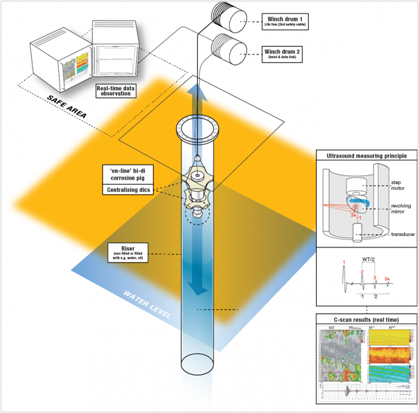

For down hole pipelines such as risers, casings and caverns, we offer an effective solution using highly advanced ultrasonic pigging technology, in combination with a winch to carry out a safe, quick and thorough inspection to evaluate the operational efficiency of your installation as well as meeting increasingly stringent regulatory standards.

Benefits of down hole inspection

- Does not require a closed system or pumping facilities

- Can be used in both filled and non-filled pipelines

- Immediate evaluation of results

- Fast and complete inspection

- Safe and full control of the tool

UT Piglet® system

The world renowned UT Piglet® developed by our partners is an online bi-directional corrosion detection pig equipped with rotating mirror which enables measurements of the complete circumference of the pipe to be taken. The acquired data including wall thickness, inner radius and distance covered can be monitored online in real-time using umbilical cables while carrying out the inspection thus allowing instant evaluation and localization of defects within the pipeline while the raw ultrasonic data is stored for detailed processing and analysis.

Applied solution

Down hole inspection is a simple operation in which the tool is lowered by gravity directly into the pipe without any elaborate preparations except for a wheel suspension unit and/or discs adapted to the width of the pipeline to centralize the tool in the pipe. In operations where the riser can be filled with water, the inspection tool can simply be lowered into the pipe by gravity using a winch assembly.

For non-filled risers the pig is set up with a seal unit and lowered into the pipe by its own weight via a winch assembly while the UT measuring head is filled with water to provide the required acoustic coupling medium for the ultrasound. To ensure that the measuring head is completely submerged, water is supplied in a constant low flow, while the sealing unit ensures the rest of the pipeline remains dry. As obtains in similar units, umbilical cable connection allows immediate viewing of inspection results in real-time while stored data can processed and analysed thereafter.