RELIABLE AND COST-EFFECTIVE

Furnace Piglet®

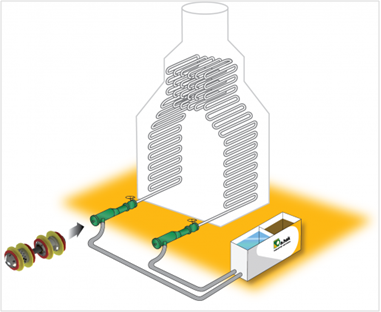

Our partners have developed special Furnace Piglet®, an intelligent free-swimming tool, capable of inspecting the tubes and bends of the furnace, with a minimum impact on shutdown time and specifically designed for furnace tubes, whether they are smooth, studded or finned. Prior to inspecting a furnace it has to be thoroughly cleaned, using our special HDT, our partner’s Decoking Technology, to remove all the cokes to ensure that the ultrasound penetrates the pipe wall.

Regular high quality cleaning and inspection increases the reliability and continuity of your furnace, ensures the integrity of the furnace and results in minimal shutdown time.

A-scan data

The innovative A-shaped, compact, lightweight and modular design of the Furnace Piglet® provides for a user-friendly, high performance, ultrasonic inspection of furnace tubes and bends with all the measurement data stored internally for eventual analysis and presentation in both tabular and graphical formats.

Advantages of using the Furnace Piglet®:

- Inspection time has minimum impact on shutdown time.

- Passing bend radii ≥ 1.0 D (smaller on request).

- Bi-directional, compact, lightweight, modular design.

- In-house developed, tested and operated.

- Reporting within 24 hours.

- Reporting conforms to API579, ASME FSS-1/2007.

- Reporting and inspection executed by qualified NDT specialist.

- Storage of raw A-scan data to enable accurate and reliable data analysis.

- C-scan of full furnace in report.

- Corrosion growth comparison capabilities.

Ability to modify the tool for specific situations