MAKING ROUTING OF HOT JOBS

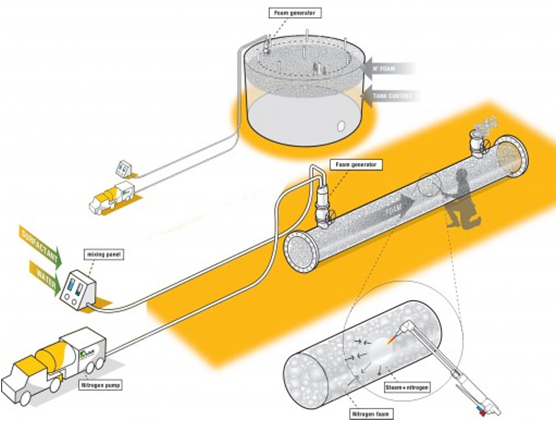

Nitrogen foam inerting provides a safe working environment for carrying out “hot” operations and maintenance in the presence of hydrocarbons, especially in respect of tanks and other enclosures. The process involves continuous injection of nitrogen in form of high expansion foam into the system to create an inert atmosphere. It is fast, reliable, cost-effective and safe and does not require the system to be empty during operation.

ADVANTAGES OF NITROGEN FOAM INERTING

– Tanks or systems can potentially stay online while being modified

– Replacement of flammable vapours inside a system

– Hot work can be carried out safely

– Faster than cold cutting methods

– Systems are made rapidly inert

– Nitrogen foam mixture is biodegradable

– Nitrogen foam is stable and visible

– No risk of explosion

A SAFETY SOLUTION YOU CAN TRUST

Nitrogen foam is stable, visible and biodegradable. During deployment, which operating procedure would have been determined in details by our specialist, the level and density of foam are controlled by a mixing panel to ensure sufficient production. Upon completion of the hot work, the foam disintegrates into water, surfactant and gaseous nitrogen which can be drained from the process item and dried if required.