WHY PIPELINE PIGGING?

Pipeline pigging’ or ‘pigs’ refers to several tools, usually propelled through the line, to perform a specific action inside the pipeline.

While build-up of foreign materials in a pipeline can cause a reduction in flow, it can also cause a rise in energy consumption due to high pressures, or even plug the pipeline. In the worst case it can cause cracks or flaws in the line with disastrous consequences, such as spills and the many associated dangers.

Our Partners build the best pig for the job.

From the construction phase until abandonment, all pipelines require pigging at certain moments and we carefully select the best pig for the job or where required build tailor-made pigs for specific jobs to guarantee the best results.

For pipelines without launchers and receivers, we also provide temporary installations, which will ensure a safe pipeline pigging process.

The following pigs will pass through a pipeline at some stage during its life span.

Gauging pigs

These are used to gauge the pipes for dimensional control before welding.

Intelligent pigs

As well as caliper pigs, we often use what are called intelligent pigs, which can register not only anomalies in dimensions, but also the pipeline’s exact location in three dimensions. In addition, it can measure the actual wall thicknesses for future comparison and determine wall thickness loss due to wear and corrosion.

Bidi pigs

These are bidirectional pigs used to empty horizontal drillings and transport gauge plates to ensure integrity of internal dimension. When construction is complete, the line will be hydro tested using bidi pigs.

Spheres, bidi pigs, brush pigs, magnet pigs, foam pigs, turbo pigs

During the production phase, debris from the product(s) may form obstructions that need to be removed. The debris can be in the form of wax, which if acted upon quickly, can be easily removed using spheres or bidi pigs equipped with or without spring loaded brushes.

Foam pigs

These are used for cleaning to remove mud, water, rust, welding slag etc. with the choice of pig dependent on the anticipated contamination and eventual pipe wall coating.

Caliper pigs

After completion of construction and prior to commissioning, a caliper (intelligent) pig is run to identify obstructions due to damage of any pipe section..

Gel pigs

This pigging method involves the use of a gelling agent in combination with cleaning agents. Often gel pigging is a solid solution for pipelines that cannot be cleaned with normal pigs. The gelled mass can be propelled through different shapes and dimensions, with the gel able to continuously adapt to the pipeline’s shape.

PIGGING THE NON-PIGGABLE

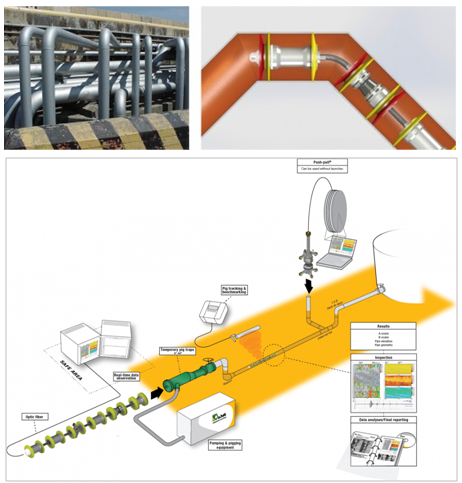

This is one of the specialties of our partner, which provides a suitable solution for the inspection of non or un-piggable pipelines and we are proud to bring the technology to the local environment. Using the piglet developed by our partner, a highly versatile inspection tool on a mobile platform for use anywhere in the world on short notice, the system applies a contact-free ultrasonic measuring head that is able to scan the full surface of the pipe wall, whereby high-resolution options can be realized seamlessly.

The ultrasonic system is based on direct ultrasonic measurement with time of flight (TOF) measurement to gather absolute wall thickness.

Simultaneously, the centralized set-up of the UT-head allows measurement of the pipeline’s geometry, detecting any deformation like ovalities, dents and buckles.

The system stores the raw A-scan data of each measurement for later interpretation thereby allowing time for detailed analysis for defects and allowing re-evaluation while eliminating errors due to algorithm induced analysis.

Where required, the system can be run free-swimming or tethered, for real-time observation of the inspection and short-term feedback on the results for immediate on-site decision making.

For the inspection of short pipe sections without the need for temporary pigging and pumping equipment, we have a hand-fed, push-pull system which can be applied with minimum downtime and yields results instantly.