PIGGING THE NON-PIGGABLE

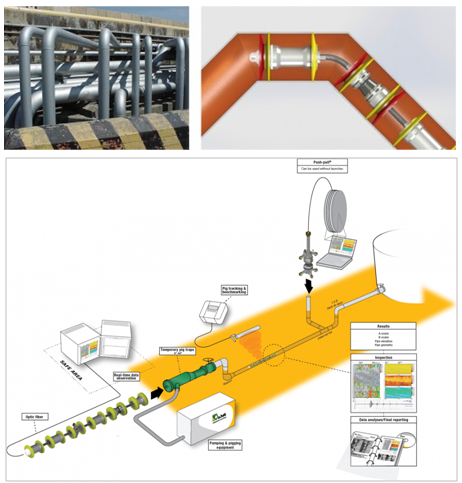

This is one of the specialties of our partner, which provides a suitable solution for the inspection of non or un-piggable pipelines and we are proud to bring the technology to the local environment. Using the piglet developed by our partner, a highly versatile inspection tool on a mobile platform for use anywhere in the world on short notice, the system applies a contact-free ultrasonic measuring head that is able to scan the full surface of the pipe wall, whereby high-resolution options can be realized seamlessly.

The ultrasonic system is based on direct ultrasonic measurement with time of flight (TOF) measurement to gather absolute wall thickness.

Simultaneously, the centralized set-up of the UT-head allows measurement of the pipeline’s geometry, detecting any deformation like ovalities, dents and buckles.

The system stores the raw A-scan data of each measurement for later interpretation thereby allowing time for detailed analysis for defects and allowing re-evaluation while eliminating errors due to algorithm induced analysis.

Where required, the system can be run free-swimming or tethered, for real-time observation of the inspection and short-term feedback on the results for immediate on-site decision making.

For the inspection of short pipe sections without the need for temporary pigging and pumping equipment, we have a hand-fed, push-pull system which can be applied with minimum downtime and yields results instantly.